Polyurethane equipmentCurrent Position:Home Page > Polyurethane high pressure foaming machine

|

Performance characteristics of two-component polyurethane high-pressure foaming machine:

1. Low speed and high precision metering pump, accurate discharge;

2. Flow rate can be adjusted flexibly;

3. Advanced head structure, reliable performance, convenient operation and simple maintenance;

4. Computer controller is adopted to control the operation smoothly;

5. Directional design for different products, widely used.

Machine head: adopt self-cleaning l-type mixing head, needle type adjustable nozzle, v-type layout jet nozzle, high pressure collision mixing principle to ensure full mixing of components.

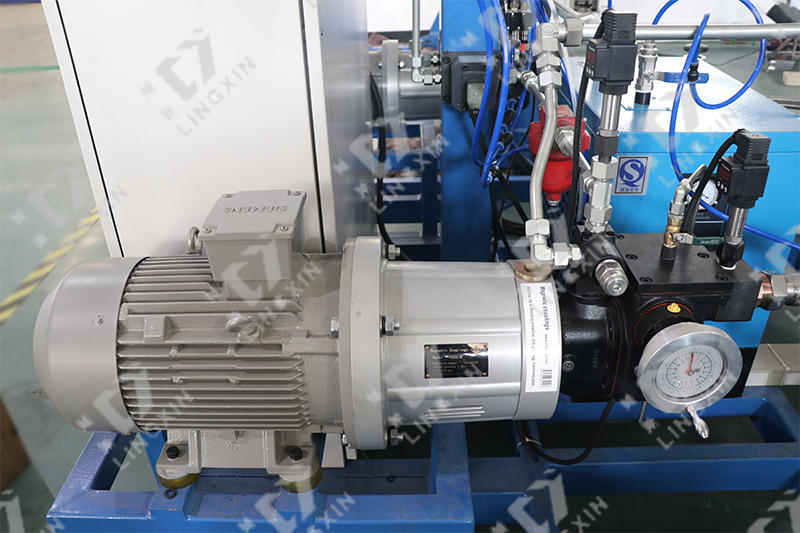

Metering pump, frequency conversion motor: high precision oblique shaft type axial piston variable pump, accurate measurement, smooth operation. Siemens motor, with durable components, long service life, beautiful and unique appearance, modular installation.

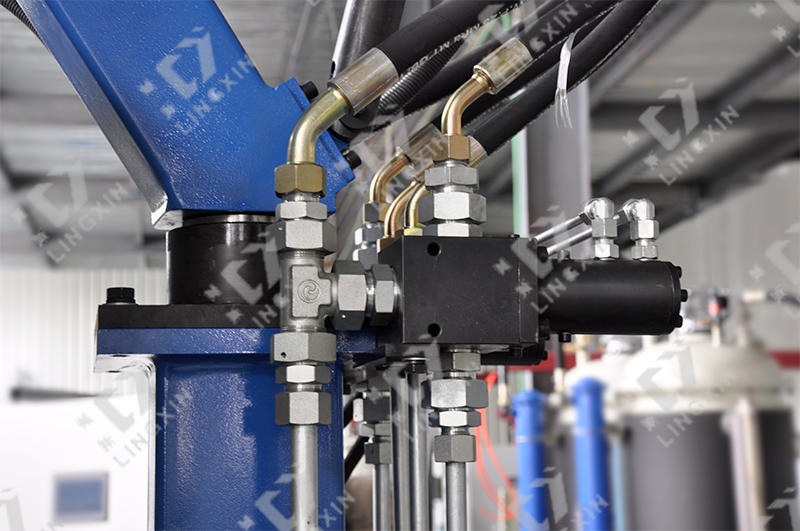

High and low pressure switching valve: when the material is not injected, the high and low pressure two-way valve makes the material A and B in the low-pressure circulation state; When feeding, the high and low pressure transfer valve operates rapidly, making A and B feed liquid change from low pressure circulation to high pressure circulation. Automatic switching of high and low voltage can reduce equipment wear and energy consumption, improve the service life of foaming equipment, reduce costs.

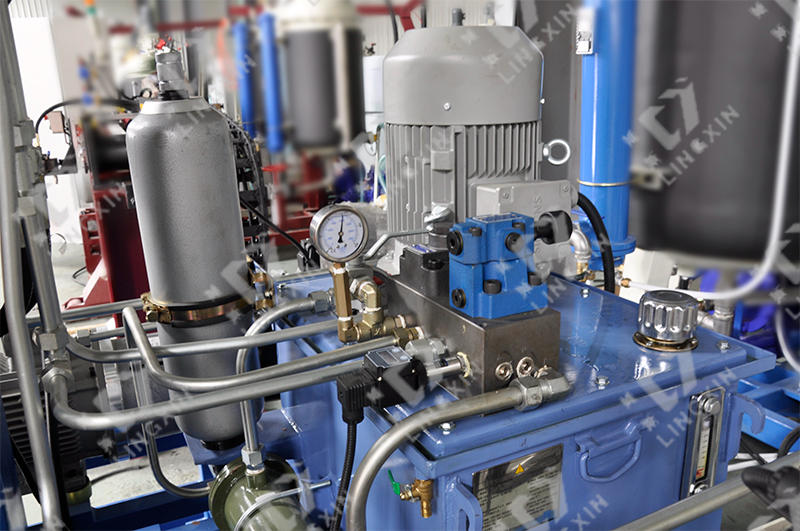

Hydraulic station: hydraulic source device composed of hydraulic pump, drive motor, oil tank, direction valve, throttle valve, overflow valve, etc., or hydraulic device including control valve. Supply oil according to the flow direction, pressure and flow required by the driving device, and the hydraulic system can realize various prescribed actions.