company newsCurrent Pocation:home > company news

The life application of polyurethane foaming machine equipment still has correct

The application of polyurethane foaming machine equipment in life in combination with the domestic scientific research institutions continue to improve and improve. Now the domestic market sales of polyurea coating with no solvent, no pollution, high reaction type protection and other characteristics. Ground polyurethane foaming machine equipment consists of two components, A kind of A, B, solvent-free, fast curing of elastic waterproof material of green environmental protection, on the basis of film forming different reactive groups are divided into play high spraying polyurea (plain) (JNC) and high elastic waterproof coating spray polyurethane (urea) (commonly known as half polyurea elastic waterproof coating,), divided into Ⅰ and Ⅱ according to physical properties. Components A and B are mixed and ejected in the spray gun of the special spraying equipment to form elastomer waterproof film by rapid reaction curing.

Component A of high projectile spraying (pure) polyurea waterproof coating is A semi-prepolymer prepared by reaction of hydroxyl terminated compound with isocyanate. Component B is A mixture composed of amino terminal resin and amino terminal chain extenders, and shall not contain any hydroxyl components and catalysts. However, it is allowed to contain A small amount of pigment and dispersed auxiliary polyurethane field foaming machine equipment waterproofing coating. Part B is a mixture of hydroxyl terminated resin or amino terminated resin and amino terminated chain extenders. Part B may contain catalysts to improve the reactivity of the reaction. A small amount of pigment and dispersed auxilary are allowed. This product is required when the film is made of special professional construction machinery coating forming, its excellent physical and chemical performance, convenient construction technology, anti-water system integrity, as well as the environmental protection is a kind of traditional protective materials and any other technical reach, is widely used in urban subway, high speed railway bridge, tunnel, water conservancy machinery, Marine chemical, waterproof, anti-corrosion, wear resistance of dual-use items "two a resistant to" project. At present, with the improvement of material consumption level of residents, people's requirements for living environment are constantly changing. Environmental comfort, safety and green environmental protection have become the leading direction pursued by modern people. Traditional home outfit coating, abandon by market place gradually.

Because, traditional coating already cannot be in satisfying contemporary indoor special repair demand. Toxic coating, pungent smell coating, inferior coating and other words appear, let a person listen to and fear, and also have a very serious impact on the human body. Now, in its place, is a very safe performance of polyurea coating.

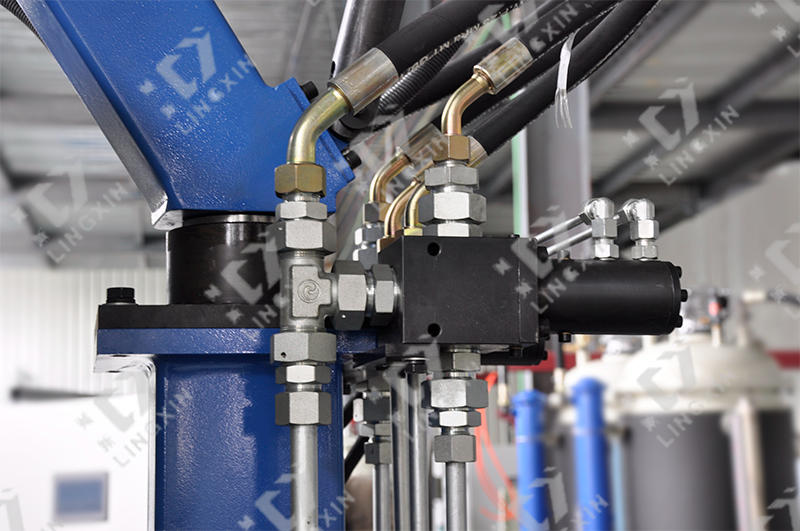

At present, small polyurethane spraying machine is very common in the market, and our manufacturer is a small polyurethane spraying machine manufacturers, the production and processing of small polyurethane spraying machine is also a certain operating standards, master the correct operation method to meet more applications. Small polyurethane coating machine products have very good coating effect in the current market, we are manufacturer of small polyurethane coating machine is simple, the function is all ready, also equipped with foaming process equipment, the operation of small polyurethane coating machine also has a track record, only to ensure that the use of formal methods, can be in the moment have good application effect of spray application.

Spray hair is a more common method, this method can be sprayed wall, roof and cold storage is a very good spray method. Casting method is also one of the more common methods, the method of casting on site without dismantling mold, casting on site without dismantling mold is more common, and can achieve good insulation effect. Dry hanging method is one of the commonly used methods in current life. It is very necessary to apply dry hanging method to spray in the building wall of oil keel. The sticking rule is that the polyurethane rigid foam insulation composite board is fully bonded through foam, which can play a good architectural application in concrete and masonry structure. As long as the right method, then the spray work will have twice the result with half the effort.