company newsCurrent Pocation:home > company news

Polyurethane board production line

Continuous polyurethane sheet wire

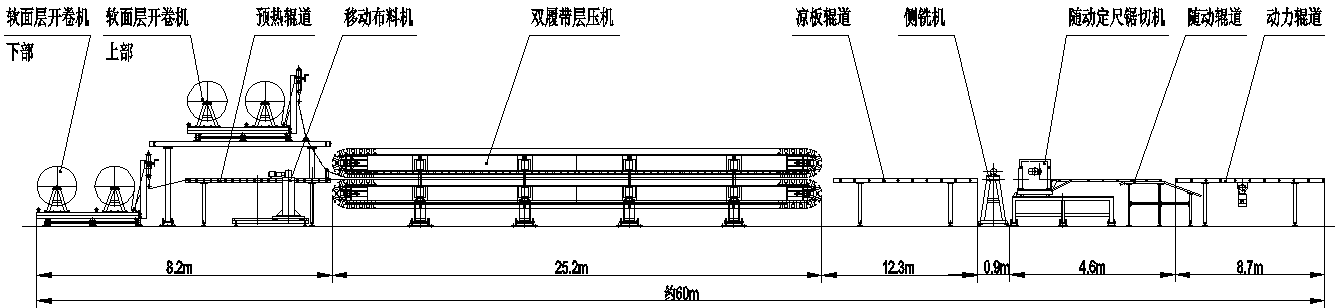

Continuous PU plate production line is composed of the following parts:

1. Surface material uncoiler

2. Loading trolley

3. Pressure device

Preheat oven

5. Metering equipment

6. Reaction mixture distribution device

7. Raw material storage and temperature control equipment

8. Dual track system

9. Plate cutting system

10. Plate unloading and packing system

The process description

(upper part) uncoiling → delivery → cutting → laminating → pressing rib → roller forming

Steel plate heating → coating → foaming, curing, molding in the laminating machine → sawing → turning, stacking → finished product packaging

(lower part) uncoiling → delivery → shearing → laminating → pressing rib → roller forming

The main use of continuous plate is: industrial buildings (such as industrial plant) building heat insulation, building external wall insulation waterproof decoration integrated board, shutter door board, cold storage, central air conditioning duct. The thickness of plank is 20-150mm commonly.

Non-continuous polyurethane sheet

Discontinuous method, also known as batch method, is suitable for the processing of plate with high production rate or thicker, larger size and more complex structure. During the operation of the discontinuous laminating machine, in-situ injection of foam solidification is carried out in the mold between two plates, and the product is finally taken out. Discontinuous polyurethane sandwich laminating machine is 6 meters in common, the longest can do 12 meters, can also be changed according to customer needs.

In order to increase the output, our company combined with the advantages of a variety of laminating machine design and manufacturingLXPU-CT3T series. The intermittent production line of polyurethane insulation board mainly includes three parts: molding machine, foaming machine and laminating machine.

In the production, the steel coil is unrolled into the molding machine and then cut off, and the bottom plate + upper plate + six-layer pressing mechanism is manually placed to form a closed body, which is then compressed through the roof mechanism, and then injected into the molding machine by PU foaming machine. When the three boards are injected and solidified on site, the other three boards are loaded and unloaded, which is also called "three in and three out". This machine is characterized by small equipment volume compared with continuous polyurethane sandwich plate production line, economical price, flexible plate surface size, suitable for the production of specially designed plates and low output requirements, and suitable for the construction of cold storage type building polyurethane color steel sandwich plate production.